In the competitive landscape of cosmetic packaging, the vessel is often just as critical as the formulation it holds. For brands developing high-performance skincare, the airless pump bottle has graduated from a luxury novelty to an industry standard. Unlike traditional dispensing systems, airless technology addresses specific chemical and mechanical challenges associated with preserving sensitive ingredients.

This guide examines the engineering behind airless pump bottles, the tangible benefits for product stability, and the customization options available through OEM/ODM manufacturing.

The Mechanics: How Airless Technology Works

To understand the value of an airless pump, one must first look at the traditional alternative. Standard lotion pumps rely on a dip tube and atmospheric pressure; as the user pumps, air enters the bottle to replace the displaced product. This introduction of air creates a pathway for oxidation and contamination.

The Non-Pressurized Vacuum System

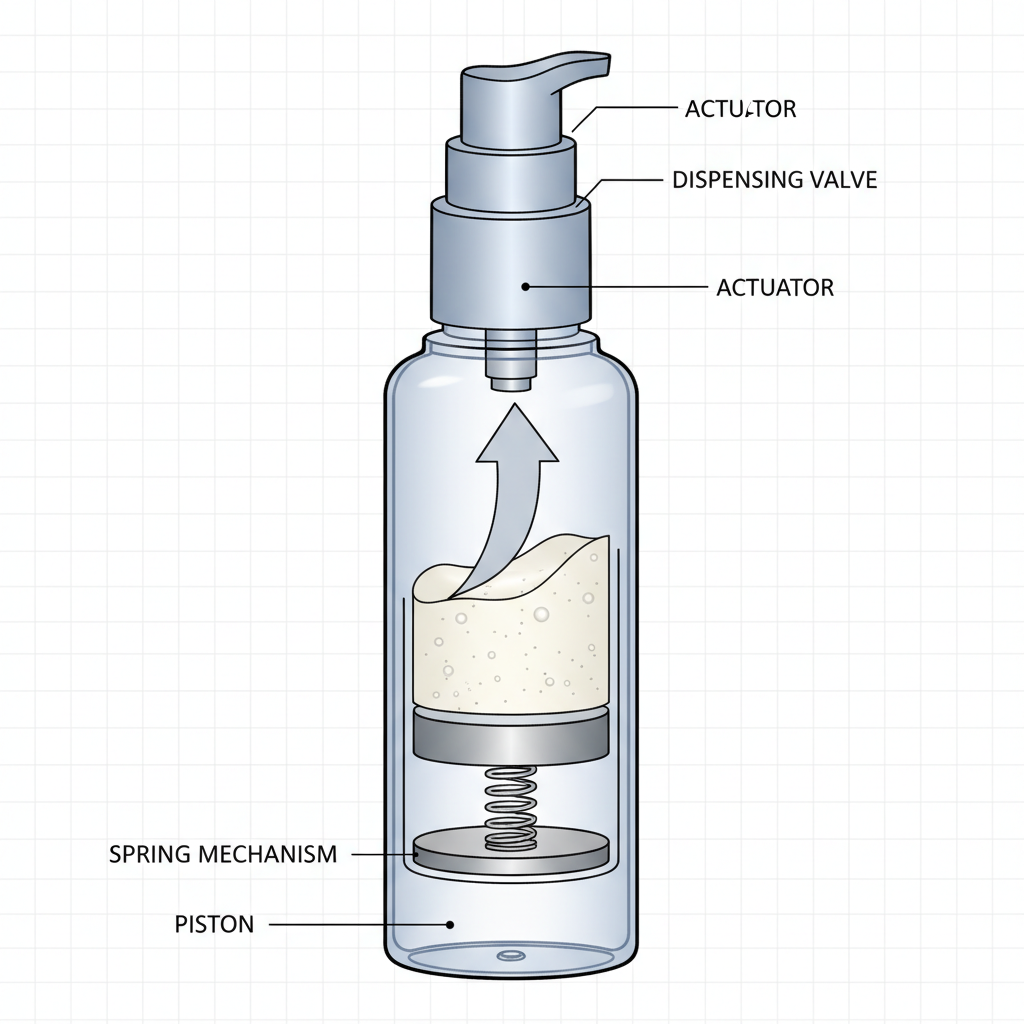

Airless pump bottles utilize a non-pressurized vacuum dispensing system. They do not use a dip tube. Instead, the mechanism typically consists of three main components:

- The Piston: A disc seated at the bottom of the bottle.

- The Pump Engine: A valve system integrated into the actuator.

- The Vacuum Effect: When the actuator is depressed, it expels the product from the chamber. This creates a vacuum state that pulls the piston upward.

As the consumer dispenses the product, the piston rises, pushing the remaining formula toward the top. This ensures the product remains isolated from external air intake throughout its usage cycle.

Why Formulators Switch: Preservation and Stability

The primary driver for the adoption of airless packaging is the rising popularity of unstable, active ingredients in skincare, such as Vitamin C (ascorbic acid), Retinol, and various peptides.

Preventing Oxidation

Oxidation is the rapid degradation of ingredients upon exposure to oxygen. For a Vitamin C serum, oxidation can turn a clear, potent formula into a brown, ineffective liquid within weeks. By eliminating the back-flow of air, airless pumps significantly extend the shelf life of these sensitive formulations without requiring excessive artificial preservatives.

Contamination Control

Because the system is closed, users cannot introduce bacteria into the bottle via finger contact, nor does the bottle inhale airborne contaminants. This is particularly relevant for “clean beauty” brands that may use milder preservative systems, making the formula more susceptible to bacterial growth if packaged in jars or standard bottles.

The Consumer Experience: Evacuation and Precision

Beyond chemical stability, airless pumps solve mechanical frustrations often cited by consumers regarding traditional packaging.

- Near 100% Evacuation: Traditional dip tubes often leave 10% to 15% of the product at the bottom of the bottle, inaccessible to the user. The rising piston mechanism in airless bottles scrapes the sidewalls clean, ensuring nearly total product usage. This is a strong selling point for premium-priced items.

- 360-Degree Dispensing: Since the system relies on a vacuum rather than gravity, airless bottles function in any position—even upside down.

- Precise Dosing: High-quality airless pumps dispense a consistent dosage (e.g., 0.2ml or 0.5ml) per stroke. This allows brands to provide accurate usage instructions, essential for potent clinical treatments.

OEM/ODM Customization Capabilities

For brands looking to source these components, the aesthetic versatility of airless bottles is vast. Manufacturers providing OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) services can adapt the basic airless structure to fit specific brand identities.

Material Selection

While the internal piston and pump engine are complex, the outer shell offers flexibility:

- PP (Polypropylene): A common, cost-effective, and chemically resistant choice.

- Acrylic (PMMA): Offers a glass-like transparency and weight, ideal for luxury positioning.

- PCR (Post-Consumer Recycled) Plastics: Many suppliers now offer airless bottles made from recycled materials to meet sustainability goals.

Decoration and Finishing

Customization options typically include:

- Color Matching: Pantone matching for the bottle body, collar, and actuator.

- Surface Treatments: Matte spraying, soft-touch coatings, or UV metallization for a metallic look.

- Branding: Silk-screen printing and hot stamping are standard for applying logos and ingredient lists directly to the packaging.

Sourcing Considerations for B2B Buyers

When selecting a manufacturing partner for airless packaging, several logistical factors come into play alongside design.

Viscosity Testing

While airless pumps handle a wide range of viscosities, from watery serums to thick creams, compatibility testing is mandatory. Extremely viscous products may require specific actuator nozzle designs to prevent clogging, while very thin liquids need tight tolerances to prevent leakage.

MOQ and Lead Times

Sourcing directly from manufacturers usually involves Minimum Order Quantities (MOQs). These can vary based on whether the item is a stock mold or a custom tool. Lead times are also a critical planning factor, often encompassing production, quality control, and shipping. Brands should request samples early in the development phase to validate the pump’s priming speed and dosage accuracy.

Certifications

Ensure your manufacturing partner holds relevant ISO certifications (such as ISO 9001 for quality management or ISO 14001 for environmental management). Compliance with regional regulations (such as FDA or EU packaging directives) is non-negotiable for global distribution.

Conclusion

The airless pump bottle is more than a premium aesthetic choice; it is a functional necessity for modern, active skincare formulations. By preventing oxidation, ensuring hygiene, and maximizing product usage, it protects the brand’s reputation for quality. Whether developing a new line or upgrading existing packaging, partnering with an experienced OEM/ODM provider ensures that the technical specifications align perfectly with the product’s viscosity and the brand’s market positioning.

Ready to elevate your product packaging? Request a quote / Get a sample today to explore our range of customizable airless solutions.